Là thiết bị cốt lõi để sản xuất các sản phẩm viên nén dược phẩm và thực phẩm hiện đại, Máy ép viên tự động Bạn đang dẫn đầu đổi mới sản xuất trong ngành dược phẩm, chế biến thực phẩm và hóa chất với hiệu suất vượt trội và công nghệ tiên tiến. Những thiết bị này không chỉ cải thiện đáng kể hiệu quả sản xuất mà còn đảm bảo sự ổn định của chất lượng sản phẩm, đồng thời giảm đáng kể chi phí nhân công và lãng phí nguyên liệu thô. Bài viết này sẽ cung cấp cho bạn cái nhìn sâu sắc về cách máy dập viên tự động có thể đạt được bước nhảy vọt về hiệu quả sản xuất thông qua đổi mới công nghệ.

Máy dập viên tự động là thiết bị sản xuất hiện đại tích hợp công nghệ cơ khí, điện tử, điều khiển tự động và các công nghệ khác, chủ yếu dùng để ép vật liệu dạng bột hoặc dạng hạt thành dạng viên rắn có hình dạng và kích thước xác định. Máy được sử dụng rộng rãi trong sản xuất dược phẩm, chế biến thực phẩm, công nghiệp hóa chất điện tử và các ngành công nghiệp khác, chẳng hạn như sản xuất các loại viên thuốc, sản phẩm dinh dưỡng và sức khỏe, phụ gia hóa học, sản phẩm bánh kẹo, v.v.

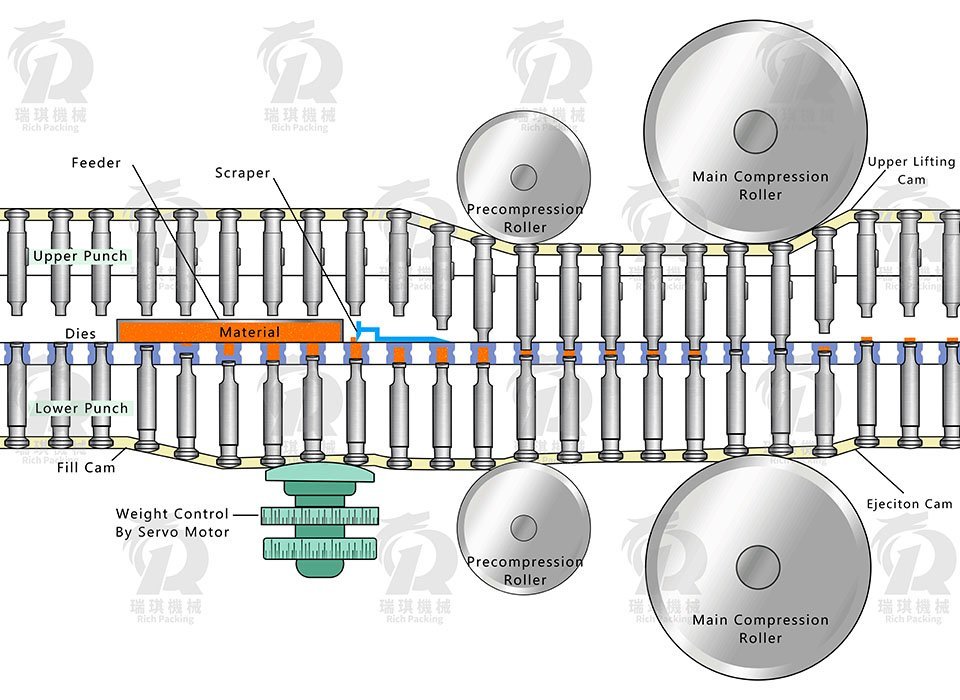

Máy ép viên tự động chủ yếu bao gồm hệ thống cấp liệu, hệ thống ép, hệ thống điều khiển, v.v. Hệ thống cấp liệu có nhiệm vụ đo lường và vận chuyển nguyên liệu thô một cách chính xác đến khu vực khuôn ép; hệ thống ép sử dụng lực cơ học mạnh để ép nguyên liệu thô thành hình dạng và thông số kỹ thuật mong muốn thông qua khuôn trên và khuôn dưới ở giữa; hệ thống điều khiển giám sát và điều chỉnh toàn bộ quá trình sản xuất theo thời gian thực, đảm bảo tính ổn định và hiệu quả sản xuất. Các bộ phận này phối hợp với nhau để tạo thành một hệ thống sản xuất máy ép viên tự động hiệu quả và chính xác.

Cơ chế cốt lõi của máy dập viên tự động tốc độ cao để cải thiện hiệu quả

Lý do máy ép viên tự động có thể cải thiện đáng kể hiệu quả sản xuất chủ yếu là nhờ thiết kế kỹ thuật tiên tiến và hệ thống điều khiển chính xác. Sau đây, chúng tôi sẽ thảo luận chi tiết về cơ chế cốt lõi của máy ép tờ tự động để cải thiện hiệu quả từ bốn khía cạnh.

Máy dập viên tự động sử dụng cảm biến có độ chính xác cao và hệ thống điều khiển tiên tiến để đo lường và phân phối nguyên liệu chính xác. Việc kiểm soát chính xác này không chỉ đảm bảo tính đồng nhất của chất lượng sản phẩm mà còn giảm đáng kể lượng nguyên liệu bị lãng phí.

Cụ thể, việc kiểm soát chính xác máy dập viên tự động được thể hiện ở các khía cạnh sau:

Kiểm soát trọng lượng: Hệ thống kiểm soát áp suất và chiết bột có độ chính xác cao đảm bảo sai số trọng lượng trên mỗi viên thuốc được kiểm soát trong phạm vi rất nhỏ, thường là ±0,5% hoặc thấp hơn.

Kiểm soát mật độ: Kiểm soát chính xác mật độ của viên nén bằng cách điều chỉnh áp suất và độ sâu chiết rót để đảm bảo độ hòa tan và khả dụng sinh học của sản phẩm.

Kiểm soát độ dày: Cảm biến dịch chuyển chính xác được sử dụng để theo dõi và điều chỉnh độ dày của viên thuốc theo thời gian thực nhằm đảm bảo tính nhất quán của thông số kỹ thuật sản phẩm.

Thiết bị thủ công hoặc bán tự động truyền thống thường dẫn đến việc sử dụng quá mức nguyên liệu thô hoặc sản phẩm không đạt tiêu chuẩn do lỗi vận hành hoặc độ chính xác của thiết bị không đủ, trong khi máy dập viên tự động có thể giảm thiểu những vấn đề này. Đồng thời, hệ thống điều khiển có thể tự động điều chỉnh tốc độ nạp liệu và lực ép theo các thông số cài đặt sẵn, tránh lãng phí nguyên liệu thô và ép quá mức. Việc kiểm soát chính xác này không chỉ cải thiện tỷ lệ sử dụng nguyên liệu mà còn giảm chi phí sản xuất và ô nhiễm môi trường, đồng nghĩa với việc tiết kiệm chi phí đáng kể cho sản xuất hàng loạt.

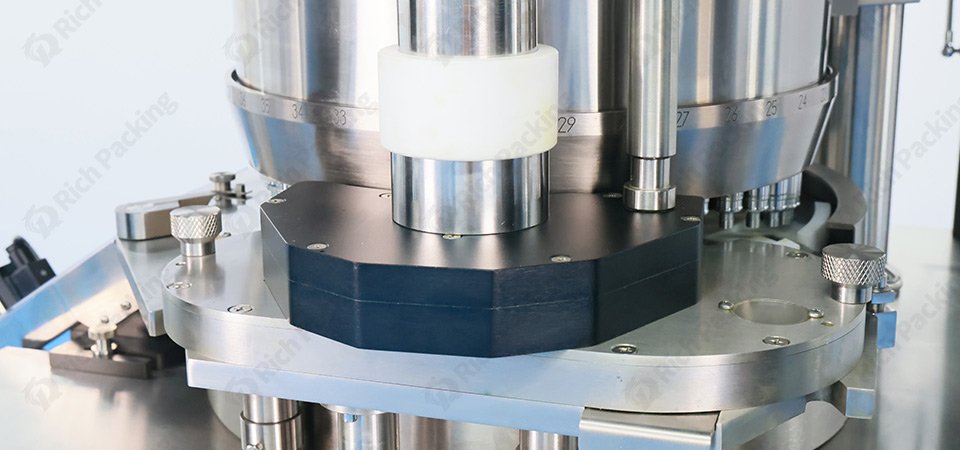

Một tính năng quan trọng khác của máy dập viên tự động là khả năng dập tốc độ cao. Máy dập viên tự động hiện đại thường được trang bị 40 khuôn dập, thậm chí hàng trăm khuôn dập quay, có thể dập đồng thời nhiều viên thuốc, đặc tính sản xuất liên tục giúp rút ngắn đáng kể chu kỳ sản xuất, cải thiện đáng kể tốc độ sản xuất.

Máy dập viên tự động tiên tiến có thể sản xuất hàng nghìn, thậm chí hàng chục nghìn viên mỗi phút, vượt xa các thiết bị truyền thống. Ví dụ, một máy dập viên tự động cỡ trung bình có thể sản xuất 260.000 viên mỗi giờ, trong khi một máy bán tự động cùng kích thước chỉ có thể sản xuất 30.000-80.000 viên.

Ngoài ra, máy dập viên tự động còn có những đặc điểm sau, giúp rút ngắn hơn nữa chu kỳ sản xuất:

-- Thay khuôn nhanh chóng: Máy ép viên tự động hiện đại áp dụng hệ thống thay khuôn nhanh chóng, giúp giảm đáng kể thời gian cần thiết để thay thế thông số kỹ thuật sản phẩm và một số thiết bị tiên tiến thậm chí có thể hoàn thành việc thay khuôn trong vòng 15 phút.

Sản xuất liên tục: Máy ép viên tự động có thể hoạt động 24 giờ mà không bị gián đoạn, giảm thiểu lãng phí thời gian do thiết bị ngừng hoạt động.

Điều chỉnh tự động: Thiết bị có thể tự động điều chỉnh áp suất, tốc độ và các thông số khác theo nhu cầu sản xuất, giảm thời gian điều chỉnh thủ công.

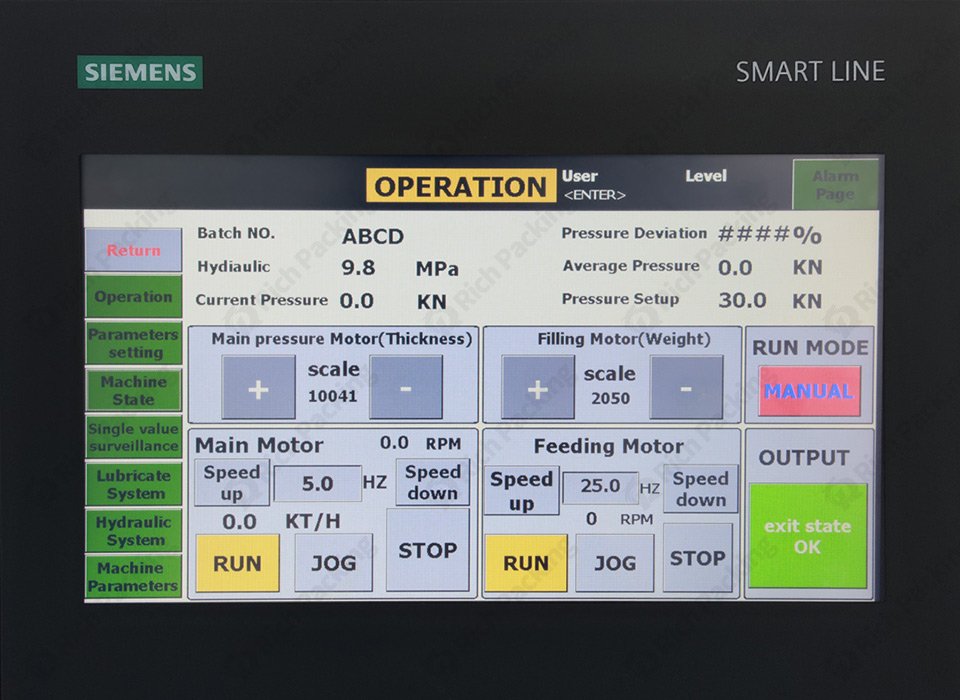

Máy tích hợp hệ thống quản lý thông minh tiên tiến, giám sát quy trình sản xuất theo thời gian thực, phân tích dữ liệu, chẩn đoán lỗi và cảnh báo sớm. Hệ thống quản lý thông minh này tối ưu hóa đáng kể quy trình sản xuất và nâng cao hiệu quả vận hành của thiết bị.

Các chức năng chính của hệ thống quản lý thông minh bao gồm:

giám sát thời gian thực: Hệ thống có thể theo dõi trạng thái hoạt động của thiết bị theo thời gian thực, bao gồm áp suất, tốc độ, nhiệt độ và các thông số quan trọng khác để đảm bảo tính ổn định của quy trình sản xuất.

Phân tích dữ liệu: Bằng cách thu thập và phân tích dữ liệu sản xuất, hệ thống có thể giúp xác định các điểm nghẽn trong sản xuất, tối ưu hóa các thông số sản xuất và cải thiện hiệu quả sản xuất.

Chẩn đoán lỗi và cảnh báo sớm: Hệ thống phát hiện kịp thời các vấn đề tiềm ẩn của thiết bị và đưa ra cảnh báo sớm để giảm thời gian ngừng hoạt động do lỗi thiết bị.

Điều khiển từ xa: Thông qua kết nối mạng, các kỹ thuật viên có thể theo dõi và điều chỉnh thiết bị từ xa để cải thiện tốc độ phản hồi.

Những chức năng thông minh này không chỉ cải thiện hiệu quả sản xuất mà còn giảm đáng kể độ khó vận hành và giảm sự phụ thuộc vào nhân viên vận hành có tay nghề cao. Theo trường hợp của một công ty dược phẩm, sau khi áp dụng hệ thống quản lý thông minh, thời gian vận hành hiệu quả của thiết bị tăng 15% và hiệu quả sản xuất tăng 20%.

Máy ép tấm tự động hiện đại có tính linh hoạt cao, có thể thích ứng với các thông số kỹ thuật, vật liệu khác nhau của nhu cầu sản xuất sản phẩm, và có thể điều chỉnh nhanh chóng các thông số sản xuất. Tính linh hoạt này cho phép doanh nghiệp phản ứng nhanh hơn với những thay đổi của nhu cầu thị trường và nâng cao tính linh hoạt trong sản xuất.

Tính linh hoạt của máy dập viên tự động chủ yếu được thể hiện ở các khía cạnh sau:

Thích ứng đa thông số kỹ thuật: Bằng cách thay đổi khuôn và điều chỉnh các thông số, máy dập viên tự động có thể sản xuất ra những viên thuốc có đủ mọi hình dạng và kích cỡ, từ viên thuốc nhỏ đến thực phẩm bổ sung dinh dưỡng lớn.

Khả năng tương thích với nhiều vật liệu: Máy ép tự động tiên tiến có khả năng xử lý nhiều loại nguyên liệu thô có tính chất khác nhau, bao gồm bột dễ chảy, vật liệu dạng hạt và thậm chí một số vật liệu khó nghiền.

Điều chỉnh nhanh: Thông qua hệ thống điều khiển máy tính, người vận hành có thể nhanh chóng điều chỉnh áp suất, tốc độ, độ sâu chiết rót và các thông số khác để đáp ứng nhu cầu sản xuất các sản phẩm khác nhau.

Quản lý lô: Máy dập viên tự động hỗ trợ sản xuất số lượng nhỏ, doanh nghiệp có thể linh hoạt sắp xếp kế hoạch sản xuất theo nhu cầu thị trường để giảm áp lực tồn kho.

Sự linh hoạt này không chỉ cải thiện hiệu quả sản xuất mà còn mang lại nhiều cơ hội thị trường hơn cho doanh nghiệp. Ví dụ, sau khi một nhà sản xuất sản phẩm chăm sóc sức khỏe áp dụng hệ thống tự động máy ép viên , nó có thể hoàn thành việc sản xuất tới 10 sản phẩm khác nhau trong một ngày, cải thiện đáng kể tốc độ phản hồi của thị trường và giành được nhiều đơn đặt hàng hơn từ khách hàng.

Là một thiết bị quan trọng trong sản xuất công nghiệp hiện đại, máy ép tờ tự động đã mang lại hiệu quả cải thiện đáng kể cho doanh nghiệp nhờ những ưu điểm cốt lõi như điều khiển chính xác, vận hành tốc độ cao, quản lý thông minh và khả năng thích ứng linh hoạt. Máy không chỉ giúp doanh nghiệp tăng năng lực sản xuất và nâng cao chất lượng sản phẩm mà còn tối ưu hóa việc sử dụng tài nguyên và nâng cao khả năng phản ứng với thị trường.

Nếu bạn có bất kỳ thắc mắc nào về công nghệ máy ép tờ tự động, hoặc muốn tìm hiểu thêm về cách áp dụng công nghệ này vào sản xuất, vui lòng liên hệ với chúng tôi. Đội ngũ chuyên nghiệp của chúng tôi sẽ tư vấn chi tiết và cung cấp các giải pháp tùy chỉnh, giúp doanh nghiệp của bạn nâng cao hiệu quả.