Máy đếm viên nén và máy đếm viên nang tự động đang cách mạng hóa cách đóng gói viên nén, viên nang và thậm chí cả kẹo dẻo, từ các hiệu thuốc nhỏ đến các nhà máy thực phẩm chức năng lớn. Bài viết này khám phá cách các máy đếm viên nang hiện đại, đặc biệt là máy đếm viên nén và máy đếm viên thuốc tự động, đang phát triển và thay đổi bối cảnh đóng gói của ngành dược phẩm.

1. Máy đếm viên nén/viên nang là gì?

Máy đếm viên nén, viên nang, còn được gọi là máy đếm viên nén, máy đếm thuốc viên hoặc máy đếm viên nang, là một thiết bị tự động được thiết kế để đếm và đóng các dạng bào chế rắn như viên nén, viên nang, viên nang mềm và thậm chí cả kẹo dẻo vào chai hoặc hộp đựng với tốc độ và độ chính xác cao.

Máy đếm viên thuốc tự động này được sử dụng rộng rãi trong các ngành sản xuất dược phẩm, thực phẩm chức năng và thực phẩm bổ sung. Chúng đảm bảo mỗi chai thuốc chứa đúng số lượng đơn vị, giảm đáng kể nhân công, sai sót của con người và lãng phí sản phẩm. Máy có nhiều model khác nhau, từ máy đếm viên thuốc để bàn đến máy đếm hoàn toàn tự động.

• Máy tính bảng để bàn dạng viên nang

• Máy đếm viên nén/viên nang tự động

• Máy đếm kẹo cao su

• Máy đếm camera tốc độ cao CCD

Máy đếm tự động, dù là máy đếm viên nén, máy đếm viên nang hay máy đếm viên thuốc, đều dựa trên công nghệ cảm biến tiên tiến và bảng rung để đảm bảo mỗi viên nén hoặc viên nang được đếm chính xác và phân phối vào chai hoặc hộp đựng. Những máy đếm và đóng viên thuốc này được thiết kế để đạt độ chính xác, tốc độ và tuân thủ các tiêu chuẩn dược phẩm.

1) Hệ thống cấp liệu rung

Quy trình bắt đầu bằng hệ thống cấp liệu rung, phân phối sản phẩm đều lên các tấm đếm. Máy đếm viên nang tốc độ cao và máy đếm viên nén sử dụng tấm rung đa kênh cho khối lượng lớn.

2

) Công nghệ đếm có độ chính xác cao

Hầu hết các máy đếm viên thuốc điện tử đều sử dụng cảm biến quang điện để phát hiện từng viên thuốc đi qua. Điều này đảm bảo mỗi viên thuốc, viên nén hoặc viên nang đều được đếm chính xác, rất quan trọng đối với máy đếm viên thuốc tại các hiệu thuốc và các hoạt động sản xuất dược phẩm năng suất cao.

3) Cơ chế loại bỏ chất thải

Các mẫu máy tiên tiến, chẳng hạn như máy đếm viên nang tự động có camera CCD tiên tiến, được trang bị hệ thống loại bỏ có thể phát hiện sản phẩm bị hỏng hoặc không đều và tự động loại bỏ, đảm bảo độ chính xác của bao bì.

4) Hệ thống chiết rót và đóng chai

Khi đạt được mục tiêu đếm, máy sẽ tự động chiết sản phẩm vào chai. Máy chiết rót viên nén và máy chiết rót viên nang tích hợp với máy đóng nắp và dán nhãn để đơn giản hóa toàn bộ quy trình đóng gói.

5) Giao diện điều khiển PLC

Người vận hành có thể theo dõi toàn bộ quy trình làm việc thông qua giao diện màn hình cảm ứng PLC, cho phép điều chỉnh các kích cỡ viên thuốc, số lượng lô hoặc thay đổi khác nhau, lý tưởng cho các doanh nghiệp sử dụng máy đếm viên của Trung Quốc hoặc nhập khẩu từ các nhà cung cấp máy đếm viên trên toàn cầu.

Máy đếm viên nén và viên nang mang lại cho các nhà sản xuất dược phẩm và thực phẩm chức năng lợi thế đáng kể trong việc hợp lý hóa sản xuất, nâng cao độ chính xác và đáp ứng các yêu cầu quy định. Dưới đây là những lợi ích chính:

• Độ chính xác cao: Máy đếm thuốc hiện đại loại bỏ lỗi thủ công, đảm bảo mỗi lọ thuốc có số lượng viên nén hoặc viên nang chính xác.

• Nâng cao hiệu quả: Máy đếm viên nang tự động có thể xử lý hàng nghìn đơn vị mỗi giờ, giúp giảm đáng kể tình trạng tắc nghẽn trong dây chuyền sản xuất.

• Tính linh hoạt: Máy đếm thuốc có thể đếm viên nén cứng, viên nang mềm, viên nang gelatin hoặc viên nang chay, viên nhai, thậm chí cả kẹo dẻo bằng máy đếm kẹo dẻo chuyên dụng.

• Tuân thủ và khả năng truy xuất nguồn gốc: Đối với sản xuất dược phẩm, máy đếm viên thuốc điện tử giúp đáp ứng các yêu cầu của GMP và cho phép theo dõi dễ dàng để kiểm toán.

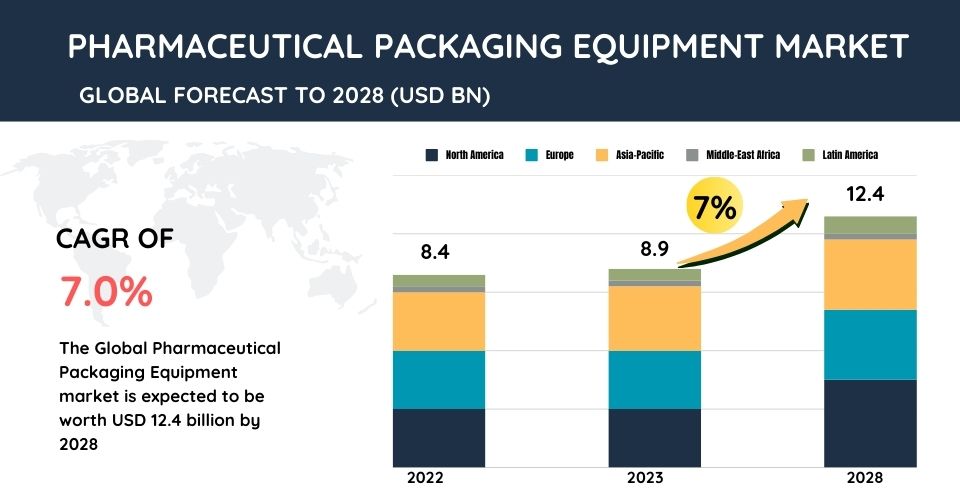

Theo báo cáo của MarketsandMarkets, ngành thiết bị đóng gói dược phẩm toàn cầu được định giá 8,9 tỷ đô la vào năm 2023 và dự kiến sẽ tăng lên 12,4 tỷ đô la vào năm 2028, phản ánh tốc độ tăng trưởng kép hàng năm (CAGR) là 7,0%. Một trong những yếu tố chính thúc đẩy sự tăng trưởng này là nhu cầu ngày càng tăng về tự động hóa trong các quy trình sản xuất, đóng vai trò quan trọng trong các ngành công nghiệp như dược phẩm, sản xuất thực phẩm và thực phẩm bổ sung.

Trong quá trình sản xuất tự động hóa này, máy đếm viên nang là một phần thiết bị chủ chốt trên thị trường này. Các động lực chính thúc đẩy sự tăng trưởng của thị trường này bao gồm:

1) Nhu cầu về dược phẩm và thực phẩm bổ sung ngày càng tăng: Dân số già hóa và nhận thức ngày càng tăng về sức khỏe đã làm tăng đáng kể nhu cầu về thuốc theo toa và thực phẩm bổ sung, đòi hỏi các giải pháp đóng gói hiệu quả và chính xác hơn.

2) Những tiến bộ trong tự động hóa: Tự động hóa trong việc đếm viên nén và viên nang giúp dây chuyền sản xuất nhanh hơn, chính xác hơn, giảm thiểu lỗi của con người và tăng hiệu quả tổng thể.

3) Tuân thủ quy định: Các nhà sản xuất dược phẩm phải tuân thủ các quy định nghiêm ngặt, bao gồm tiêu chuẩn FDA và GMP. Việc đếm tự động đảm bảo bao bì chính xác, tuân thủ quy định, bảo vệ sức khỏe người tiêu dùng và duy trì sự tuân thủ quy định.

|

Ngành công nghiệp |

Ứng dụng |

Sản phẩm được tính |

|

Dược phẩm |

- Bao bì thuốc theo toa và thuốc không kê đơn - Chuẩn bị bộ dụng cụ thử nghiệm lâm sàng - Đóng chai theo tiêu chuẩn GMP |

Viên nén, viên nang, viên nang mềm, thuốc liều đơn. |

|

Thực phẩm chức năng & Thực phẩm bổ sung |

- Đóng chai đa vitamin - Viên nang chiết xuất thảo dược - Sản xuất nhãn hiệu riêng |

Viên nang, viên nhai, viên nang mềm, viên nén collagen. |

|

Thú y |

- Đóng chai thuốc thú y - Bao bì phụ gia thức ăn chăn nuôi - Chuẩn bị thức ăn bổ sung cho thú cưng |

Thuốc bolus, viên nén, viên nang chăm sóc sức khỏe cho vật nuôi. |

|

Mỹ phẩm & Chăm sóc da |

- Bao bì thực phẩm chức năng làm đẹp răng miệng - Viên sủi chăm sóc da |

Viên uống chăm sóc da, viên uống tan trong nước, viên nang làm đẹp. |

|

Thực phẩm & Bánh kẹo |

- Đóng chai kẹo/bạc hà - Bao bì viên năng lượng - Chế biến thực phẩm chức năng |

Viên bạc hà, viên kẹo, cà phê/thực phẩm bổ sung năng lượng. |

|

Nghiên cứu & Bệnh viện |

- Chuẩn bị mẫu thử nghiệm lâm sàng - Phân phối theo lô nhỏ - Nhà thuốc trong bệnh viện |

Viên nén, viên nang, mẫu thử nghiệm. |

Khi nhu cầu về kẹo dẻo chức năng và ăn kiêng ngày càng tăng, nhu cầu về máy đếm kẹo dẻo chính xác cũng tăng theo. Một máy đếm kẹo dẻo đặc biệt đảm bảo kẹo dẻo mềm, hình dạng không đều không bị dập nát hoặc đếm sai trong quá trình đóng gói. Những máy đếm kẹo dẻo này sử dụng hệ thống phân phối và tách kẹo dẻo tùy chỉnh, cùng với các tấm rung được xử lý đặc biệt để đảm bảo độ chính xác và vệ sinh.

Ví dụ, Máy chiết rót đếm kẹo dẻo 8D từ Rich Packing đã thực hiện một số cải tiến chi tiết đặc biệt để giải quyết vấn đề dính kẹo cao su với các tính năng sau:

• Hệ thống tách keo khuấy có gai: Tách hoàn toàn các viên kẹo dẻo dính ra trước khi cho bé ăn.

• Hệ thống chống vón cục: Tránh để kẹo dẻo chồng lên nhau trước khi cho vào tấm rung.

• Tấm rung 3 giai đoạn có rãnh phủ Teflon: Tránh để kẹo cao su dính vào tấm pin trước khi đưa vào kênh đếm cảm biến quang điện.

• Cổng xả PTFE mở rộng với hệ thống rung: Đảm bảo kẹo dẻo được đóng chai trơn tru, tránh vấn đề tắc nghẽn.

Việc lựa chọn máy đếm viên thuốc hoặc máy đếm viên nang phù hợp là rất quan trọng để duy trì hiệu quả, độ chính xác và khả năng mở rộng trong dây chuyền sản xuất của bạn. Cho dù bạn là một thương hiệu thực phẩm bổ sung mới thành lập hay một nhà sản xuất dược phẩm lớn, một thiết bị phù hợp sẽ đảm bảo độ chính xác, giảm thiểu lãng phí và hỗ trợ tuân thủ quy định.

|

Loại máy |

Tốt nhất cho |

Các tính năng điển hình |

|

Máy đếm thuốc thủ công |

Các hiệu thuốc nhỏ, phòng xét nghiệm, bệnh viện |

Khay đếm cơ bản, giá thành thấp, tốc độ và khối lượng hạn chế. |

|

Máy đếm hoàn toàn tự động |

Các nhà máy sản xuất thực phẩm bổ sung/dược phẩm quy mô lớn |

Hệ thống đa kênh, công suất cao, tích hợp toàn bộ dây chuyền. |

|

Bộ đếm đa kênh |

Hoạt động tốc độ cao đòi hỏi nhiều làn đường |

Độ chính xác cao, kênh có thể tùy chỉnh (4, 8, 12, 16+), tính năng chống bụi. |

|

Quầy viên nang để bàn |

Phòng thí nghiệm R&D, nhà sản xuất theo hợp đồng |

Thiết kế nhỏ gọn, màn hình hiển thị kỹ thuật số, hoạt động cắm và chạy. |

|

Máy đếm camera CCD |

Đóng chai dược phẩm và thực phẩm chức năng có độ chính xác cao. |

Sử dụng camera CCD công nghiệp tốc độ cao để đếm dựa trên hình ảnh; cực nhanh với khả năng phát hiện lỗi theo thời gian thực. |

|

Nhân tố |

Chi tiết |

|

Khối lượng sản xuất |

Chọn máy đếm viên nén để bàn cho các lô sản xuất vừa và nhỏ. Đối với sản lượng lớn, hãy chọn máy đếm viên nén hoàn toàn tự động với bảng rung đa làn. |

|

Loại sản phẩm |

Đảm bảo máy hỗ trợ sản phẩm cụ thể của bạn, viên nén cứng, viên nang mềm, viên nang, viên nang trong suốt, v.v. Máy tiên tiến có nhiều kênh và hệ thống chống bụi để có hiệu suất tốt hơn. |

|

Độ chính xác và tốc độ |

Hãy tìm các tính năng như cảm biến quang điện, tính năng chống bụi và hệ thống xả êm để đảm bảo đếm nhanh và chính xác. |

|

Dễ sử dụng |

Màn hình điều khiển cảm ứng, thiết kế dạng mô-đun giúp tháo lắp và bảo trì dễ dàng, cảnh báo lỗi thông minh và thay đổi bộ phận không cần dụng cụ giúp cải thiện hiệu quả vận hành và giảm thời gian chết. |

|

Tuân thủ quy định |

Máy móc phải tuân thủ các tiêu chuẩn GMP, CE và FDA, đặc biệt là đối với mục đích sử dụng trong dược phẩm và thực phẩm chức năng. |

|

Khả năng tích hợp |

Nếu bạn đang tự động hóa dây chuyền sản xuất của mình, hãy đảm bảo máy có thể tích hợp với máy đảo chai, máy chèn chất hút ẩm, máy đóng bông, máy đóng nắp và hệ thống dán nhãn. |

Việc lựa chọn một nhà sản xuất máy đếm viên nén đáng tin cậy sẽ đảm bảo hiệu suất lâu dài, hỗ trợ sau bán hàng tốt hơn và tuân thủ quy định. Dưới đây là một số nhà cung cấp uy tín trên toàn cầu và tại Trung Quốc, nổi tiếng với thiết bị chất lượng:

|

Nhà sản xuất |

Quốc gia |

Điểm mạnh |

|

Kem |

Hà Lan |

Giải pháp đếm tốc độ cao cho dược phẩm và thực phẩm chức năng; hệ thống quang học tiên tiến. |

|

IMA |

Ý |

Máy cao cấp; một phần của dây chuyền đóng gói hoàn toàn tự động. |

|

Kirby Lester (Capsa) |

Hoa Kỳ |

Máy đếm thuốc nhỏ gọn và bán tự động, lý tưởng cho các hiệu thuốc và bệnh viện. |

|

RichPacking |

Trung Quốc |

Máy hoàn toàn tự động giá cả phải chăng với nhiều tùy chọn kênh và tuân thủ GMP. |

|

Ruidapacking |

Trung Quốc |

Đáng tin cậy cho người mua có nhu cầu về chất lượng cao nhưng tiết kiệm ngân sách; Hiệu suất tuyệt vời và giá cả phải chăng. |

Từ máy đếm viên thuốc trong các hiệu thuốc nhỏ đến máy đếm viên nang tự động trong môi trường công nghiệp, việc chuyển đổi sang tự động hóa không còn là lựa chọn tùy ý. Đầu tư vào máy đếm viên nén và viên nang không chỉ tăng hiệu quả mà còn nâng cao chất lượng sản phẩm và uy tín thương hiệu. Cho dù bạn cần máy đếm viên thuốc, máy đếm kẹo dẻo, hay máy đếm và đóng viên thuốc hoàn chỉnh, chưa bao giờ có thời điểm nào tốt hơn để khám phá thị trường.