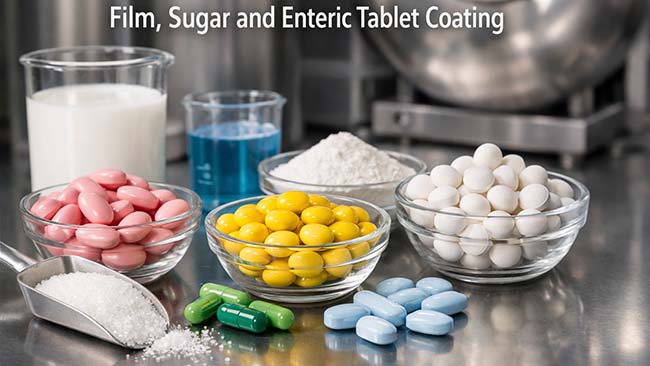

In modern solid dosage manufacturing, tablet coating is far more than a cosmetic step. A well-designed coating layer protects sensitive active ingredients, improves stability, masks unpleasant taste and odour, and helps patients identify and swallow tablets more easily. Among all techniques used today, film coating, sugar coating and enteric coating are the three classic approaches that most formulators and manufacturing engineers work with every day. For equipment suppliers and production teams, understanding when and how to use each coating type is essential for designing robust processes and choosing the right coating machinery.

Tablet coating is the process of applying one or more thin layers of polymers, sugars, waxes or functional excipients onto compressed cores. The coating solution or suspension is sprayed onto tablets while they tumble in a rotating perforated pan or move through another type of coating system. Warm, conditioned air dries the deposited droplets to form a uniform surface layer that changes how the tablet behaves in the hand, in the blister and in the patient’s body.

At the simplest level, coating prevents mechanical damage, reduces dust, and makes tablets look smooth and uniform. In more advanced applications, coating controls how fast the drug dissolves, where it is released in the gastrointestinal tract, and how well the product can survive moisture, light and oxygen during its shelf life. Because coating touches both formulation science and process engineering, it is one of the key links between R&D, production and packaging.

Film coating has become the dominant approach for most new tablet products. In this method, a relatively thin polymer layer is sprayed onto the cores, usually from a water-based dispersion. Typical film-forming polymers include HPMC, PVA and acrylic systems, combined with plasticisers, colourants and sometimes functional pigments for opacity or light protection.

Compared with older technologies, film coating offers several practical advantages. The coating layer is thin and light, so tablet size and weight only increase modestly. Processing time is relatively short, which helps keep batch cycle time under control and supports high throughput production. The technology is compatible with automatic control of inlet air temperature, spray rate, pan speed and exhaust conditions, making it easier to run consistent, repeatable batches. For many products, a simple non-functional film is enough to improve swallowability, mask mild taste and prevent scuffing in bottles and blisters.

In addition, film coated tablets are often the best partner for blister packaging lines. Because the surface is smooth, hard enough and not excessively fragile, they flow well through feeding systems and can withstand sealing forces in the blister machine. When the formulation requires extra protection, the film layer can also be combined with high-barrier blister materials to build a strong defence against moisture and light.

Sugar coating is one of the oldest tablet coating techniques and is still used for certain legacy brands and markets where a high-gloss, candy-like appearance is valued. In sugar coating, the core tablet is built up through multiple applications of syrup and powder layers, often passing through sealing, subcoating, smoothing, colouring and polishing stages. The result is a thick, rounded shell with a shiny surface and excellent taste masking.

However, this attractiveness comes at a cost. Sugar coated tablets typically gain significant weight and volume, which can make them harder to package in modern blisters and bottles. The process itself is time-consuming and labour-intensive, with long pan times and many manual interventions. Sugar coating also exposes the tablet to more moisture during processing, which can be problematic for water-sensitive actives.

For these reasons, many manufacturers have shifted existing sugar coated products to modern film coating where regulations and markets allow. Even so, understanding sugar coating remains important, because older products may still be in production and some customers or regions still associate the glossy sugar shell with premium quality or brand identity.

An enteric coating keeps the tablet intact as it passes through gastric acid and is formulated to dissolve only once it encounters the higher-pH conditions of the small intestine. To achieve this behaviour, formulators use pH-sensitive polymers such as cellulose derivatives or methacrylic acid copolymers that remain intact at low pH and ionise at higher pH. The goal is either to protect the stomach from local irritation or to protect acid-sensitive drugs from degradation in gastric fluid.

This type of coating is particularly important for products such as certain proton pump inhibitors, some antibiotics, enzymes and probiotics. In these cases, releasing the drug too early in the stomach can dramatically reduce efficacy or increase side effects. A well-designed enteric layer therefore becomes part of the therapeutic design, not just a cosmetic addition.

Because enteric coating has stricter performance requirements, process design and equipment capability play an even larger role. Uniform film thickness, robust adhesion to the core, controlled drying and appropriate plasticiser content all influence whether the tablet will pass pharmacopoeial tests for delayed release and acid resistance.

Although all three methods put a layer on the tablet, they behave very differently in production and in the market. The table below summarises some of the most important differences.

|

Factor |

Film coating |

Sugar coating |

Enteric coating |

|

Main purpose |

Protection, appearance, basic release |

Taste masking, high-gloss appearance |

Acid resistance, intestinal release |

|

Typical thickness |

Thin |

Thick, multi-layer |

Medium, functional |

|

Process time |

Moderate |

Long (many steps) |

Moderate to long |

|

Weight gain |

Low to medium |

High |

Medium |

|

Moisture exposure |

Lower |

High (repeated syrup applications) |

Moderate |

|

Typical applications |

Most modern solid dosage products |

Legacy brands, specific markets |

Acid-sensitive or gastric-irritant actives |

In practice, film coating is now the first choice for the majority of new tablets because it balances protection, process efficiency and patient acceptability. Sugar coating is usually reserved for existing products where the brand image is tightly linked to a particular look and mouthfeel, or where the marketing strategy explicitly favours a traditional appearance. Manufacturers choose an enteric coating system when they need to control the site of drug release within the gastrointestinal tract for specific clinical or stability requirements.

From an equipment and operations perspective, film and enteric coating are easier to automate and scale in modern perforated pan systems. Sugar shell processes can be run on the same basic hardware, but they often require different spray regimes, pan loading strategies and operator skills, which is one reason why fewer new products choose this route.

Not every tablet needs a coating. For some simple, physically robust formulations with good taste and adequate stability, an uncoated core can be perfectly acceptable. However, as soon as stability, patient experience or branding become more demanding, coating quickly shows its value.

The comparison below highlights some typical differences.

|

Aspect |

Uncoated tablets |

Coated tablets |

|

Stability |

More exposed to moisture, light and abrasion |

Extra barrier against moisture, light and mechanical damage |

|

Patient experience |

May feel rough, taste bitter or have odour |

Smoother swallow, better taste masking, improved appearance |

|

Branding and ID |

Limited colour and logo options |

Flexible colours, finishes and printing |

|

Process complexity |

Simpler, fewer steps |

Added coating step and controls |

Coating also improves how tablets behave on downstream equipment. Smooth, harder surfaces tend to generate less dust, flow more consistently and survive high-speed bottling and blistering with fewer defects. This is one reason why equipment suppliers increasingly design tablet presses, tablet coaters, blister machines and cartoners as integrated lines rather than isolated units.

Even the best formulation will not perform well if the coating process and equipment are poorly designed. A tablet coating machine provides much more than a rotating drum. It coordinates pan speed, spray pattern, airflow, temperature and exhaust to create a controlled environment in which the coating can build up evenly and repeatably on every tablet in the batch.

Key elements typically include a perforated coating pan with carefully designed baffles, a set of precision spray guns with adjustable droplet size and spray angle, and an air handling unit that conditions inlet air temperature, humidity and volume. A programmable control system links these parameters into recipes so that operators can run different products with consistent settings and traceability. For enteric products, the ability to follow a defined temperature and drying profile is critical to avoid brittleness or incomplete film formation.

Suppliers such as Rich Packing design automatic tablet coating machines to integrate these features with cGMP-friendly construction. Smooth stainless steel contact parts, optimised airflow channels and options for clean-in-place or wash-in-place reduce the time needed for changeover and lower the risk of cross-contamination. When a tablet coater is selected and configured correctly, it becomes a reliable tool for delivering stable film and enteric coatings that perform as intended in pharmacopoeial testing and actual use.

Q1. What is the main difference between film coating and sugar coating?

Film systems apply a relatively thin polymer layer in a shorter, more controllable process. Sugar layers are much thicker, built up through multiple syrup and powder applications, and give a very glossy, candy-like surface. Film processes usually offer better efficiency, lower weight gain and easier automation, while sugar shells provide stronger taste masking and a traditional look at the expense of time and complexity.

Q2. When should I choose enteric coating instead of a normal film coat?

Enteric systems are used when either the drug is unstable in gastric acid or it can irritate the stomach lining. In these cases, the coating must keep the tablet intact in acid for a defined period and then allow rapid release in the higher pH of the intestine. If the main goal is only to improve appearance or basic stability, a conventional film layer is usually sufficient.

Q3. Are sugar coated tablets still relevant in modern pharmaceutical manufacturing?

Yes, but their role is narrower than in the past. Sugar shells are still used for some legacy brands and for markets where patients strongly associate the glossy appearance and taste with premium quality. However, because the process is slower and more labour-intensive, many companies prefer to convert suitable products to film systems when they update formulations or launch new lines.

Q4. Can one tablet coating machine handle film, sugar and enteric coating?

In principle, one perforated pan coater can be configured to run different coating types if its spray system, air handling and controls are flexible enough. In practice, most manufacturers focus on film and enteric work on a given machine and reserve sugar processes for specialised lines, because sugar shells demand different process times, loading strategies and cleaning routines.

Q5. What are the most important parameters to control in a tablet coating process?

For all three coating types, inlet air temperature, spray rate, atomisation pressure, pan speed and exhaust conditions are critical. Together, they determine how wet or dry the tablet bed becomes, how fast the solvent evaporates and how uniformly the film builds. Stable control of these variables, supported by a well-designed pharmaceutical tablet coating machine, is the foundation of robust coating performance.

Tablet coating, especially film coating, links formulation, process and packaging in a single, thin layer that strongly influences how tablets look, feel and perform. Film systems have become the modern standard because they offer a good balance of protection, efficiency and flexibility, while sugar and enteric coatings remain valuable tools for specific taste masking and targeted release needs. By understanding the strengths and limitations of each approach, and by pairing them with capable, well-controlled coating equipment, manufacturers can design solid dosage products that satisfy both regulatory expectations and patient experience over the full product life cycle.